Commitments

Safety Isn’t a Big Enough Word

At Monsanto, the safety of our employees has always been a core value of our culture. Our Pledge is a cornerstone on which we built our business and a fundamental part of our present and future.

To put it simply, we don’t think it’s acceptable for people to be injured on the job, and it’s vital that we manage our business in such a way that our employees are educated to make better choices at work, on the road or at home with their families. We strive for zero injuries, not just fewer injuries. And while we haven’t attained zero yet, we think it’s worth striving for every day.

Our safety initiatives and programs are created to support our core value of safety. We continually evaluate and re-evaluate our process and work hard to elevate the conditions in our sites worldwide to protect our employees and reduce injuries. As part of Monsanto’s overall safety and health requirements, each of our sites have a Safety and Health Program Management System. In organizing and administrating the health and safety programs at each site, committees or teams are established with the responsibilities for the various elements of the site’s safety programs. This increases involvement, engagement and ownership in safety programs. GRI LA 6 Almost 25 percent of our employees are involved in safety and health committees and the ongoing implementation of our health and safety programs.

GRI LA MAThe Monsanto Star Award – Above and Beyond Safety

The Monsanto Star program demonstrates our commitment to safety. A homegrown effort, this certification program provides employees the opportunity to earn safety certifications for their site. Originally built off the U.S. Occupational Safety and Health Administration (OSHA) Voluntary Protection Program (VPP), our certification provides both U.S. and international sites the opportunity to showcase, on a multi-year basis, their improving practices and procedures.

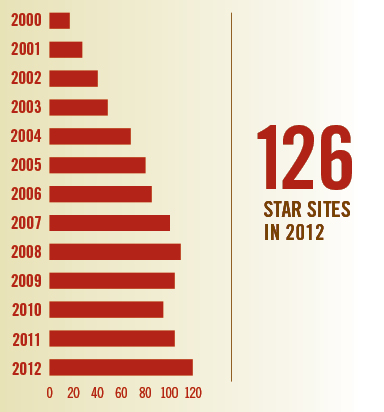

With more than 442 sites globally, we strive to certify all of them and bring them into the Monsanto Star certification program. In 2012 we had a total of 126 sites that earned the Star recognition.

Total Star Sites By Year

Source: Monsanto tracking database of STAR sites

Additional Accolades

In addition to the Monsanto Star program, our teams are proud of all the independent accolades and awards our sites have been given. It’s a further testament to our desire to put safety above all else, and cement our reputation as one of the leaders in agriculture site safety.

Some of the awards received in 2012:

The Zero Accident Award — Awarded by the Ministry of Manpower & Transmigration of the Republic of Indonesia, this was bestowed upon our Tangerang plant for achieving 1.4 million hours of operations free from accident.

CICM Responsible Care Award — Given by the Chemical Industries Council of Malaysia, this categorized award highlights excellence in safety. Our Pasir Gudang plant won three gold awards for pollution prevention, process safety code and employee health and safety code. This is the eighth year our plant has won three gold awards, and the sixth year in a row.

Superstar among Stars — Our Luling, Louisiana site was given this award for being better than 75 percent of the industry when it came to safety in their region. This is a truly elite award given only to those who achieve a stellar safety record.

Contractor Excellence — The Heart of Zachary Award was received by two of our routine contractors. They were graded not just on attaining a year without recordable incidents, but are graded on nine elements: injury performance, near miss reporting, continuous improvement, safety task assessment, site safety plan, supervisory safety skills training, hazard recognition, annual supervisor performance evaluation and hand safety.

Dave Snively, Executive Vice President, General Counsel and Secretary presenting a Monsanto Star Award in St. Louis, Missouri.

Acquiring Companies and Their Safety Risks

The business of agriculture carries inherent risks, and companies manage these risks differently. When we acquire a new business, we assess its safety culture and identify areas for improvement. We work with our partners to heighten education and awareness about safety and strive for continuous improvement. We find that when we standardize safety procedures at our new sites, we reduce injury by a substantial rate.

The Lockout/Tagout Solution

Hand injuries can be debilitating, and are the number one injury that our sites record and respond to. In an effort to limit the number of debilitating hand injuries, Monsanto instituted a step change in our lockout/tagout program for our employees and contractors.

REDUCED INCIDENTS OF INJURY FROM 21% TO 4%

Lockout/tagout is an established procedure to reduce injury for those employees working with machinery. When servicing a machine, employees place a lock on a box or electrical outlet. This lock prevents accidental activation of the machine and also reduces the risk of an arm injury from workers placing their hands inside a machine. A global risk assessment was conducted, focusing on opportunities in our lockout/tagout program in our Row Crops Manufacturing business. The assessment consisted of managers conducting spot surveys of employees performing lockout/tagout and teams surveying our equipment for improvements, which generated thousands of opportunities globally and allowed us to make our lockout/tagout program safer.

This program reduced incidents of injury from 21 percent to 4 percent. And while that number is far from zero, we’re proud of the improvement, and we keep looking for more ways within this procedure and others to continue to reduce the number of accidents.

Proper ergonomic practices for office workers also prevent hand injuries incurred from repeated tasks. Monsanto-trained employees, called “Ergonauts,” meet with each new employee to set up the workspace and teach good ergonomic habits.

Proud to Be Our Neighbor’s Keeper

Monsanto knows we have a responsibility to take care of those not only working at our sites, but those who live in the communities in which we have those sites. Our chemical business knows this well. We handle a number of high hazard materials when we produce pesticides and chemicals in our product line. When we create, handle, load and unload these materials, we have procedures and stringent processes in place to protect the environment and our neighbors.

A Process Safety Technical Team consisting of key technical contacts from each of our chemical manufacturing sites meets regularly to share best practices and process safety information. We have also adopted the safety metrics recommended by the Center for Chemical Process Safety.

As we continue to improve our safety procedures, our people periodically employ a consulting firm to use a process safety cultural survey tool at all of our chemical manufacturing sites. This tool allows them to compare our sites to internal and industry benchmarks. The results help identify areas of improvement in goals, responsibilities, procedures, equipment, process safety reporting, safety values, worker empowerment and process safety training. These variables help us identify where we need to improve and how best to go about making our sites the safest in the world. We work hard every day to earn their trust and respect of the communities surrounding our plants.